The coil technology is the heart of the tool-manic. With a new generation of coil technology, SCHÜSSLER offers an efficient, environmentally friendly, and tool-friendly shrinking process. Optimized heating parameters and shorter heating times guarantee optimal runout accuracy and a longer tool-life of the shrink fit chuck. Due to 25-30 % reduced energy consumption compared to other models the shrinking process is also significantly more environmentally friendly and energy efficient.

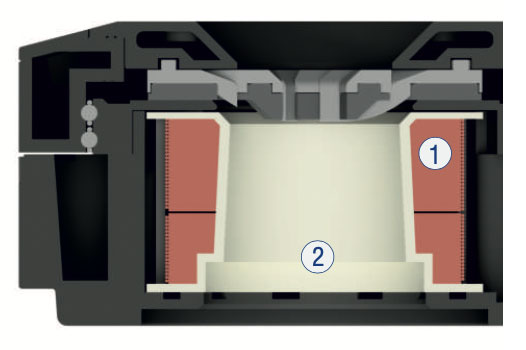

1. Induction coil with two separate windings. The windings are built separately and can therefore be also controlled separately. Thus, the shrinking process can be done by either the upper or the lower or with both windings together. That leads to optimized heating parameters for each shrink fit chuck, shorter heating periods, and lower chuck temperatures. Due to that, shorter cycle times, short cooling times, and a longer tool life can be achieved.

2. Optimized energy input into the shrink fit chuck,

as only the relevant clamping area is heated. Less heat

radiation downwards.

* Only applicable when using the shrinking parameters of the S30.